Mga produkto

High Precision Tungsten Carbide Polished Rods Round Bar

Panimula ng Produkto

Ang mga carbide rod ay pangunahing ginagamit para sa drill bits, end-milling cutter at winches. Maaari rin itong gamitin para sa pagputol, panlililak at mga tool sa pagsukat. Ito ay ginagamit sa papel, packaging, pag-print, non-ferrous metal processing industriya. Bilang karagdagan, ito ay malawakang ginagamit sa machining high speed steel cutter, carbide milling cutter, cemented carbide cutter, NAS cutting tool, aviation cutter, cemented carbide bits, milling cutter core bits, high speed steel, taperd milling cutter, metric milling cutter, micro end milling cutter, hinge pilot, electronic tool,carbide rotary file, cemented carbide tool, atbp.

Mga Detalye ng Produkto

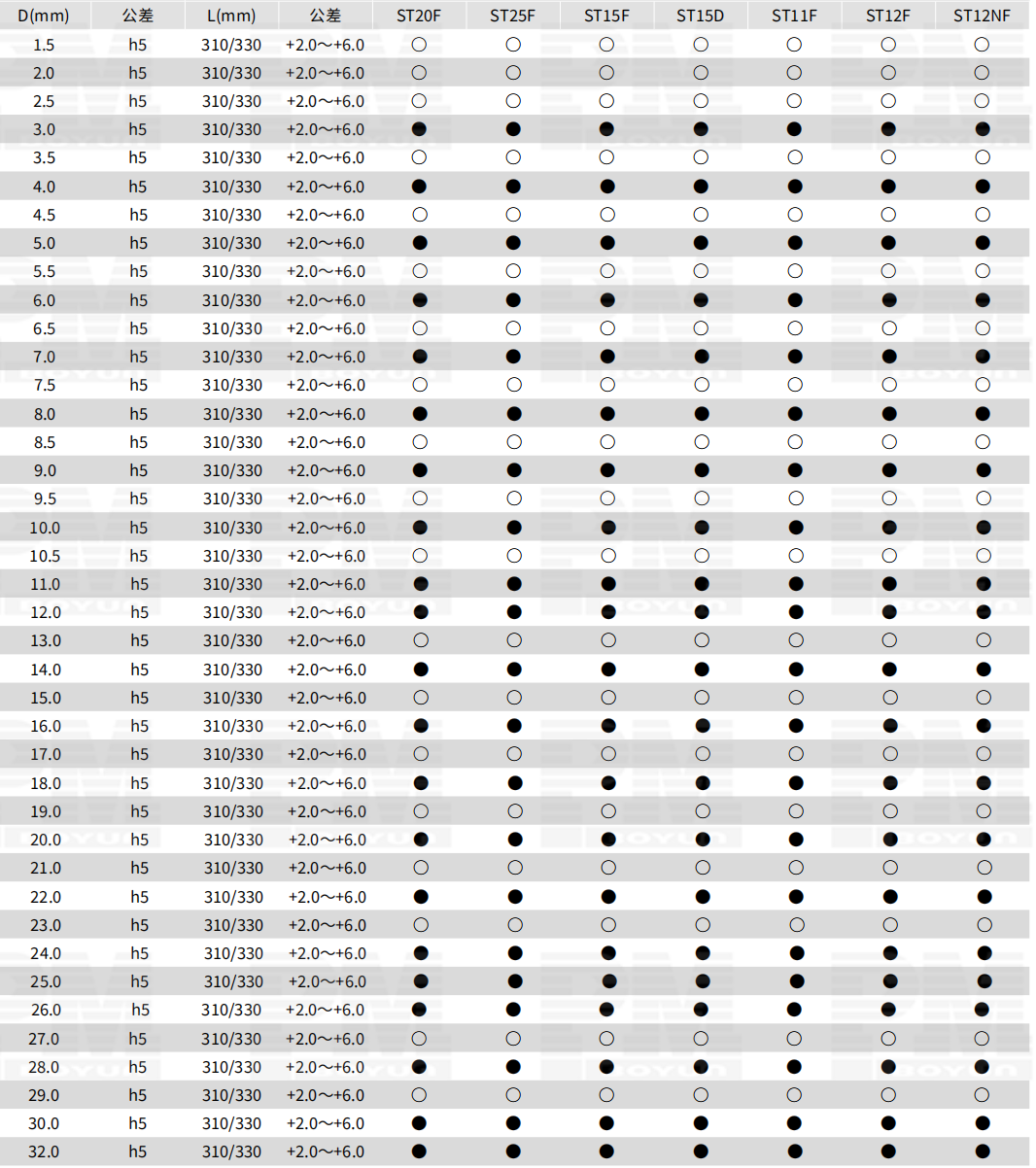

Mga Reference na Laki

Chart ng Materyal na Grado

| Grade Introduction sa Carbide Rods | |||||||

| Grade | Co% | Laki ng butil ng WC | HRA | HV | Densidad (g/cm³) | Lakas ng baluktot(MPa) | Katigasan ng bali(MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | ayos lang | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Isulat ang iyong mensahe dito at ipadala ito sa amin